Thermoseal Industries

Thermoseal IndustriesRequest A Quote

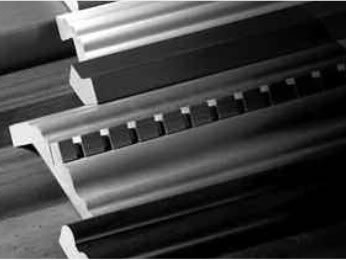

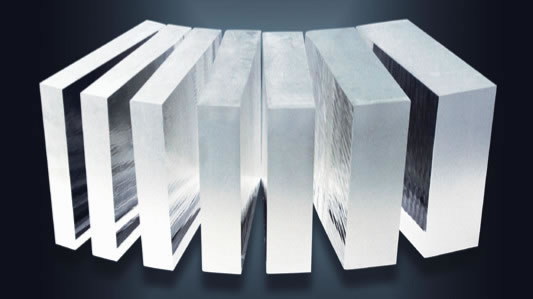

Gloucester City, NJ | 800-456-7788Thermoseal Industries holds its headquarters in Gloucester City, New Jersey, and has been at the forefront of glass fabrication since its establishment in 1956. With a rich history spanning decades, the company has earned a reputation as a leading glass fabricator known for its unwavering commitment to excellence. Specializing in the fabrication of annealed, laminated, and tempered glass, Thermoseal Industries has consistently provided high-quality solutions to a diverse array of industries. Notably, the company excels in producing insulating glass engineered to withstand extreme temperatures, making it an optimal choice for applications such as refrigeration equipment, baking ovens, and environmental test chambers. Thermoseal Industries offers a comprehensive range of glass products tailored to the distinct requirements of various industries. This includes annealed glass known for its uniform thickness and clarity, which is suitable for applications where safety concerns are less critical; laminated glass featuring an interlayer film for enhanced safety in automotive windshields, architectural structures, and industrial contexts; tempered glass, created through controlled heating and rapid cooling, providing exceptional strength for shower enclosures, storefronts, and household appliances; and insulating glass designed for energy efficiency, formed by combining multiple glass panes with a hermetically sealed space to meet the needs of applications like refrigeration equipment and environmental test chambers. In tandem with its diverse product offerings, Thermoseal Industries delivers a range of services to ensure seamless customer experiences. The company excels in custom fabrication, harnessing skilled artisans and advanced machinery to create bespoke glass solutions that align with specific customer requirements. Additionally, their team of experts provides valuable consultation and design support, assisting clients in selecting the most fitting glass type for their intended application. With a steadfast commitment to quality, Thermoseal maintains rigorous quality control measures throughout the fabrication process, ensuring each piece of glass meets industry standards and exceeds client expectations. Leveraging an efficient supply chain and logistics network, the company guarantees the punctual delivery of glass products to designated locations. Thermoseal Industries' capabilities are a result of its extensive industry experience, cutting-edge technology, and skilled workforce. With seasoned glass artisans and engineers possessing an in-depth understanding of fabrication techniques and material properties, the company creates high-performance glass products. Leveraging state-of-the-art machinery and technology, Thermoseal ensures precision, consistency, and top-tier quality in every manufactured product. Their unwavering commitment to innovation keeps them at the forefront of glass fabrication, as they continuously explore novel techniques, materials, and applications to meet evolving client needs. The company's unique ability to craft tailored glass solutions further distinguishes them as a reliable partner for clients seeking specialized and distinctive glass products.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

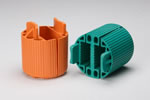

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services