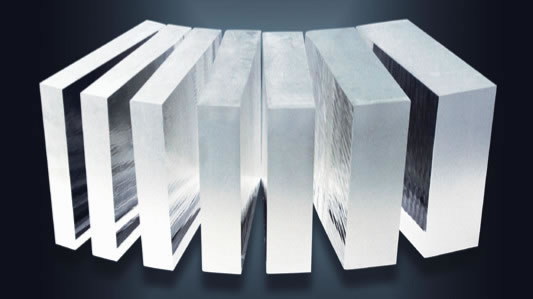

Borosilicate glass is a heat and shatter resistant material that is composed of silica and at least 5% boron oxide. Also commonly referred to as Pyrex, this type of glass is mostly used for the manufacturing of products that handle strong acids and alkalis because of its resistancy to breakage and its high chemical resistance. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

Coresix Precision Glass, Inc. is a fully integrated technical glass manufacturer specializing in high quality glass of all types. We are supported by a modern and fully integrated grinding department that can offer quality and cost effective manufacturing and fast delivery. Call us today for more information!

More Borosilicate Glass Manufacturers

Borosilicate glass is commonly used for products which are involved with high-temperature autoclaves, hot plates and open flames. Borosilicate glass as a heat resistant glass is also used to produce laboratory equipment like beakers, test tubes and telescope mirrors which are designed for processes with chemicals and heat. Aquarium heaters, flashlight lenses, microwave-safe glass and kitchen ware and precision optical lenses are examples of everyday items often made of borosilicate glass.

It is an ideal safety glass choice for many household or commercial uses as it exhibits a high temperature range for extremes of both cold and heat, and when dropped, it cracks into big pieces rather than shatters into hundreds of small splinters, making clean up safer and easier. Soda-lime glass is a popular alternative to borosilicate glass because it tends to be cheaper to produce and has many of the same properties.

Glass fabricators manufacture borosilicate glass by adding a small amount of boron or boric oxide to the traditional glass ingredients-silicate sand, soda and ground lime. During formation, the glass must be heated to 1200 degrees F, which is higher than other types of glass. Its coefficient of thermal expansion is one third that of standard glass, which reduces the material stresses caused by temperature gradients.

This makes borosilicate glass more resistant to breaking as a result of thermal shock or stress, although it will break if dropped on a hard surface or exposed to sudden and radical temperature change. Most borosilicate glass is colorless which is ideal for many of the processes for which it is used, although it can be manufactured with color for the purposes of studio glass trade.

Because it requires higher heat and more labor during production than standard glass, it is slightly more complicated to produce than regular glass. Products made of borosilicate glass tend to be more expensive, there are however numerous advantages to using borosilicate. It is able to be used for the containment of many harsh and volatile chemicals like nuclear waste. It is likely to have a longer lifespan than other types of glass because of its physical properties and therefore will prove more cost effective in the long term.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services