Quartz glass, also known as fused silica, is a type of glass that is made from pure silica. It is a highly versatile material that is used in a wide range of applications due to its unique properties, such as its high thermal stability, low thermal expansion, and high chemical resistance. In this article, we will discuss the production, varieties, benefits, and applications of quartz glass. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

Coresix Precision Glass, Inc. is a fully integrated technical glass manufacturer specializing in high quality glass of all types. We are supported by a modern and fully integrated grinding department that can offer quality and cost effective manufacturing and fast delivery. Call us today for more information!

More Quartz Glass Manufacturers

Production of Quartz Glass

Quartz glass is produced by melting pure silica at very high temperatures, typically around 2,000 to 3,000 degrees Celsius. There are several methods used to create quartz glass, including the following:

Electric Fusion Method

This method involves passing an electric current through a resistance-heated furnace that contains high-purity silica. The silica melts and then solidifies as it is cooled, forming a solid mass of quartz glass.

Flame Fusion Method

This method involves passing a mixture of gasses, such as oxygen and hydrogen, through a burner that contains high-purity silica. The silica melts and then solidifies as it is cooled, forming a solid mass of quartz glass.

Chemical Vapor Deposition (CVD) Method

This method involves depositing silica vapor onto a substrate, such as a silicon wafer, using a chemical reaction between a silicon-containing gas and an oxygen-containing gas.

The choice of method depends on the intended application of the quartz glass. For example, the electric fusion method is commonly used to produce high-purity quartz glass for use in the semiconductor industry, while the flame fusion method is used to produce low-cost quartz glass for general applications.

Varieties of Quartz Glass

Quartz glass comes in several varieties, each with its own unique properties and applications. The most common varieties include:

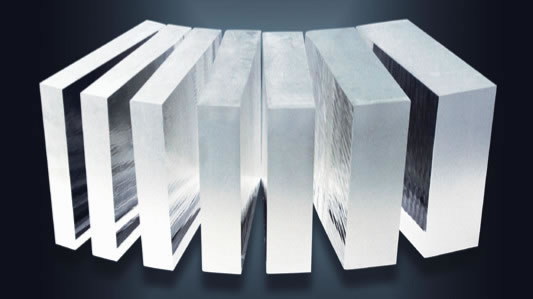

Clear Quartz Glass

This is the most common variety of quartz glass and is used in a wide range of applications, such as optical windows, lenses, and prisms.

Opaque Quartz Glass

This variety of quartz glass is used in applications where high thermal stability is required, such as in the chemical industry.

Quartz Glass Ceramics

This variety of quartz glass is produced by controlled crystallization of pure silica and is used in applications such as high-temperature heating elements and ceramic substrates.

Considerations Regarding Quartz Glass

Although quartz glass has many benefits, there are also some considerations to take into account associated with its creation and use. For example, the production of quartz glass requires very high temperatures, which can be energy-intensive and therefore expensive. In addition, exposure to fine silica dust during the production and handling of quartz glass can cause lung damage and other health issues.

Benefits of Quartz Glass

Despite the negative considerations, quartz glass has many benefits that make it an ideal material for many applications. Some of the key benefits include:

High Thermal Stability

Quartz glass can withstand high temperatures without cracking or melting, making it ideal for use in high-temperature applications.

Low Thermal Expansion

Quartz glass has a low coefficient of thermal expansion, which means that it does not expand or contract significantly when exposed to temperature changes.

High Chemical Resistance

Quartz glass is highly resistant to chemical attack, making it ideal for use in the chemical industry.

Applications of Quartz Glass

Due to these benefits, quartz glass has a wide range of applications in many industries, including the following:

Optical and Lighting Applications

Quartz glass is commonly used to produce lenses, prisms, and windows for optical and lighting applications due to its high optical purity and transparency.

Semiconductor Industry

Quartz glass is used in the production of semiconductors, such as computer chips, due to its high purity and ability to withstand high temperatures.

Chemical Industry

Quartz glass is used in the chemical industry to produce high-purity vessels, tubing, and other components due to its high chemical resistance and ability to withstand harsh chemical environments.

Medical and Dental Applications

Quartz glass is used in medical and dental applications, such as in dental implants and prosthetics, due to its biocompatibility and ability to resist corrosion.

Research and Scientific Applications

Quartz glass is used in research and scientific applications, such as in spectroscopy and microscopy, due to its high optical purity and ability to withstand high temperatures.

UV Disinfection

Quartz glass is transparent to UV-C radiation, which is used for disinfection purposes. UV-C lamps made of quartz glass are used to disinfect air, water, and surfaces in hospitals, laboratories, and public spaces.

Choosing the Correct Quartz Glass Supplier

To ensure you have the most beneficial outcome when purchasing quartz glass from a quartz glass supplier, it is important to compare several companies using our directory of quartz glass suppliers. Each quartz glass supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each quartz glass business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple quartz glass companies with the same form.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services