To manufacture glass tubes, glass fabricators or glass blowers melt glass and draw a stream of the molten material over a cylinder or cone. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

Coresix Precision Glass, Inc. is a fully integrated technical glass manufacturer specializing in high quality glass of all types. We are supported by a modern and fully integrated grinding department that can offer quality and cost effective manufacturing and fast delivery. Call us today for more information!

More Glass Tube Manufacturers

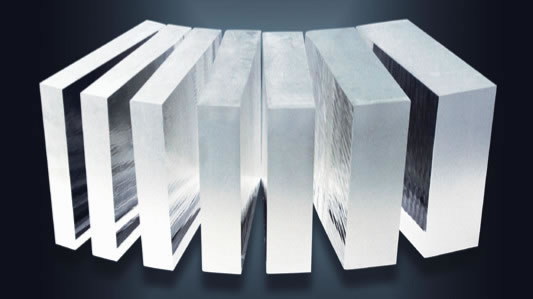

The glass mixture used to make Glass Tubes is typically made up of silicate materials with the potential for additives during the process. A stream of air keeps the molten glass from collapsing until it has hardened in the shape of a tube. As glass is a brittle material, it is necessary for glass products to undergo the process of annealing after they have been fabricated, especially in the manufacturing of heat resistant glass.

Annealing reheats and cools the glass which removes any potential areas of stress or weakness and makes the glass product more resistant to sensitivity to temperature changes. Glass tubes are hollow and are available in a variety of thicknesses and lengths. Depending on the intended application of the glass tube, the wall thickness can be adjusted accordingly. Tempered glass or safety glass tubes are likely to be thicker.

As glass is a malleable material when heated, it is possible for glass tubing to be bent or curved although this is likely to distort the cross section of the tubing. Yet the added malleability broadens the range of possible uses for glass tubes and rods. These hollow or solid stock size tubes have a number of uses including fluorescent or halogen light bulbs, sterilized tubes used for medical and laboratory purposes as well as for vials, gas transportation and material storage.

In industrial applications glass tubing is commonly used with liquids and gases to store, transport and in flow measuring applications, or in specific components of mechanical pieces such as sight glass. There are many things to consider when selecting the most suitable glass rod for a process. For example, a tube's optical properties and thermal capabilities, as well as physical and electrical characteristics.

If a tube is to be used for lighting or visual purposes, its levels of opaqueness and resistance to light are important. If a tube or rod is to undergo stress or tension in its application, then wall thickness and material strength should be considered. Density, thermal conductivity and co-efficiency, as well as electrical resistance and loss tangent for energy are further considerations, especially in precision applications such as medical operations.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services