Mirrors are used for countless applications in the commercial, technical, industrial, scientific, military and consumer industries. A mirror is a type of reflective glass that reflects rays of light, and preserves some or all of the physical characteristics of the original light. Mirrors can be manufactured in round, rectangular, spherical, and many other shapes. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

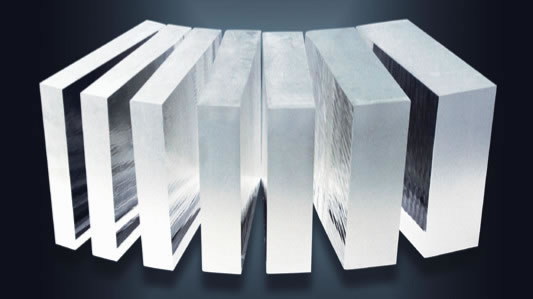

Coresix Precision Glass, Inc. is a fully integrated technical glass manufacturer specializing in high quality glass of all types. We are supported by a modern and fully integrated grinding department that can offer quality and cost effective manufacturing and fast delivery. Call us today for more information!

More Mirror Manufacturers

The reflective surfaces of mirrors come in a variety of shapes as well, such as flat, concave, or convex. Laser mirrors coated with thin layers of gold, silver, or aluminum on glass, and are capable of spliting beams of light. They are equipped with lasers that are high power and high speed, and with UV to IR spectral ranges.

Mirrors can be found in cars and trucks; in scientific, technical and optical labs and equipment; in medical settings; and in commercial and industrial settings. Industrial, technical and scientific mirrors include optical mirrors, laser mirrors, and dichroic mirrors; the latter can reflect one wavelength of light and transmit the rest. Inspection mirrors that can bend or telescope, and have joints that can swivel or rotate, allow users to see around corners and tight spots. Curved mirrors such as parabolic reflectors are used in telescopes. Convex or diverging mirrors are used for safety, in automotive side-view mirrors, hallway mirrors and on roads and driveways to allow pedestrians and motorists to see around sharp turns and corners. Such mirrors provide a wider range of view than flat mirrors.

Concave or converging mirrors have reflective surfaces that are recessed inward. They are used to focus light inward, as from a wide surface area to a single point. Such mirrors are used in a wide variety of applications, from reflecting telescopes to mirrors that magnify an image, to solar power applications to illumination purposes; spotlights, flashlights and headlamps, for example, all use concave mirrors to distribute light from a small point or source outward. Concentrated solar power generation systems utilize mirrors or lenses to gather sunlight from a large area and concentrate its energy in a small area. When the energy from sunlight is concentrated it is converted into solar thermal energy or heat, producing electricity. Currently, photovoltaic cells are used much more widely than concentrated solar power or CSP systems, but in the future CSP will undoubtedly be used to generate power on a much wider scale.

Depending on the applications the mirror will ultimately be used for, they can be fabricated from a broad range of ingredients. To manufacture the glass used in mirrors, ingredients such as silica or silicon dioxide are commonly mixed with chemicals including sodium oxide, sodium carbonate, calcium oxide or lime. The ingredients are then heated and mixed in a furnace, then cooled to a temperature where they can be shaped into different sized products. After the glass substrate of the mirror is made, it is coated with reflective materials such as silver, gold or aluminum. Copper is often used to extend the mirror’s durability, and the reflective coating on the back of the substrate is often coated with a layer of paint to protect it from various types of damage such as scratching. Dielectric or Bragg mirrors consist of multiple layers of dielectric material on a glass substrate. These mirrors are used for splitting beams into different wavelengths of light, for laser cavity mirrors and on mirror shades. Dielectric or Bragg mirrors can often be found in optical applications.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services