Mark Optics Incorporated

Mark Optics IncorporatedRequest A Quote

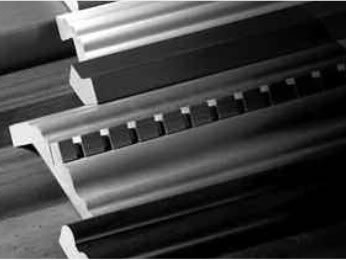

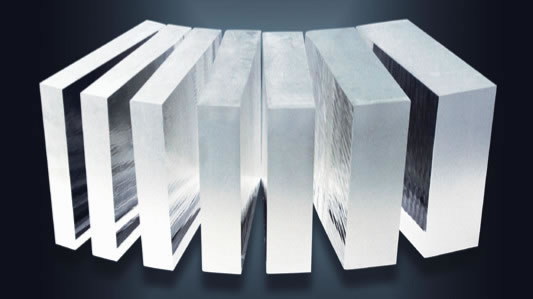

Santa Ana, CA | 714-545-6684Based in Santa Ana, California, Mark Optics Incorporated has been a respected industry leader since 1967, specializing in superior glass fabrication and fused silica substrates. With over five decades of experience, the company has earned a stellar reputation for delivering precision flat optical components and ultra-thin wafers to cater to diverse industry needs. Mark Optics is committed to providing exceptional products and services, backed by their expertise in lapping, precision polishing, CNC shaping, and more. Mark Optics offers an impressive product portfolio that caters to a wide range of industries and applications. Their key product offerings include precision flat optical components such as lenses, mirrors, prisms, and windows, which are vital elements in various optical systems, ensuring exceptional clarity and performance for imaging, laser applications, and more. Additionally, the company specializes in producing ultra-thin wafers, which find applications in semiconductor and electronics industries, serving as critical substrates for various electronic devices and sensors. Mark Optics also provides top-quality fused silica substrates with outstanding thermal and chemical resistance, making them ideal for high-temperature and demanding environments. Complementing their product range, Mark Optics Incorporated offers comprehensive services to meet and exceed customer expectations. With decades of experience in glass fabrication, their skilled team of professionals excels in creating customized high-quality glass components tailored to specific applications. Precision polishing techniques are employed to achieve the highest level of surface quality and accuracy in their optical components and wafers, ensuring that their products meet the stringent demands of various industries. Mark Optics' capabilities encompass a wide range of advanced manufacturing processes, enabling them to deliver exceptional products. Through lapping techniques, they achieve precise flatness and surface smoothness in their optical components and wafers, ensuring consistent and high-quality results. Leveraging Computer Numerical Control (CNC) shaping technology, the company can create complex and custom shapes with unparalleled precision, addressing the diverse needs of their customers. By continually investing in cutting-edge manufacturing technologies, Mark Optics remains at the forefront of the industry, ensuring that they deliver products of the highest quality and performance.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

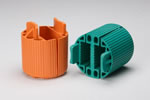

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services