Although it looks indistinguishable from normal glass, tempered glass is four to five times stronger than standard float glass. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Established in 1947, we have been providing glass cutting using very precise tolerances in order to ensure that our products are among the best. Our skilled designers and technicians are available around the clock in order to work with you from design to delivery to ensure that you are receiving a product that will fit your needs perfectly! For more information on what we may be able to do for...

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

More Tempered Glass Manufacturers

Tempered Glass: Comprehensive Guide to Strength, Applications, and Safety

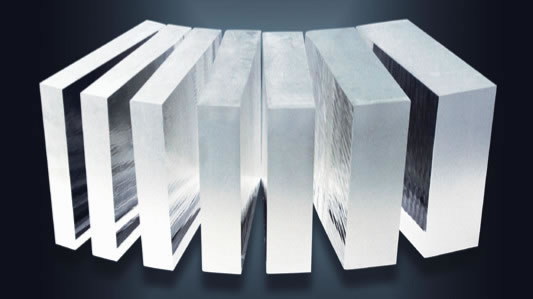

Tempered glass, also known as toughened glass, is a type of safety glass that is produced by a specialized heat treatment process. This process carefully balances the center and outer stresses of the glass, altering the internal structure of its particles to enhance both durability and safety. When tempered glass is subjected to impact, it shatters instantly into small, blunt, relatively harmless pebbles or granules, rather than sharp, jagged shards that can cause serious injury. Due to these unique properties, tempered glass is a preferred material in many industries, especially where safety glass and high-impact resistance are essential.

How is Tempered Glass Made? – The Tempering Process Explained

The production of tempered glass begins with ordinary, annealed glass. This base glass is first cut to the specified dimensions, thoroughly washed, sanded, and carefully inspected for imperfections. It is crucial to complete all fabrication prior to the tempering process since any post-tempering alterations, such as cutting or drilling, will cause the glass to shatter.

Once the glass is prepped, it undergoes a rigorous thermal tempering process:

- Heating: The glass is heated evenly in a tempering furnace to approximately 620ºC (about 1,148ºF).

- Quenching: The hot glass is rapidly cooled (quenched) with high-pressure blasts of cold air, cooling the surface more quickly than the interior.

- Result: This rapid cooling leaves the outer surfaces of the glass in compression and the inner core in tension, creating balanced internal stresses that significantly increase the glass's strength and impact resistance.

This process is carried out by professional glass fabricators with specialized equipment and expertise. The result is a product that is four to five times stronger than standard annealed glass.

Key Benefits and Advantages of Tempered Glass

Tempered glass offers numerous advantages for both commercial and residential applications. If you are considering tempered glass for your project, here are the most important benefits:

- Enhanced Safety: In the event of breakage, tempered glass crumbles into small, granular chunks that are much less likely to cause injury, making it ideal for high-traffic and public environments.

- Superior Strength: With a typical breaking strength of about 24,000 psi, tempered glass is much more resistant to impact and thermal stress compared to standard glass.

- Thermal Resistance: Tempered glass can withstand sudden temperature changes, making it perfect for applications involving heat or cold, such as oven doors and fireplace screens.

- Scratch and Impact Resistance: The toughened surface makes it more durable against scratches, knocks, and accidental bumps.

- Compliance with Building Codes: Many building codes require the use of tempered or safety glass in specific installations, particularly in public buildings, doors, and windows.

- Versatility: Available in different thicknesses, sizes, and tints to suit a wide range of architectural, industrial, and design needs.

Primary Applications of Tempered Glass

Tempered glass is widely used in settings where human safety, durability, and reliability are paramount. Its applications span various industries:

- Construction and Architecture: Used for storm doors, frameless shower enclosures, glass railings, partitions, balcony doors, and building facades.

- Automotive Industry: Essential for car side and rear windows, sunroofs, and skylights due to its shatter-resistant properties.

- Consumer Electronics: Protects screens of smartphones, tablets, laptops, and computer monitors with thin yet robust tempered glass covers.

- Home Appliances: Found in oven doors, microwave oven windows, stove tops, coffee maker carafes, and refrigerator shelves.

- Furniture: Used in tabletops, shelving, cabinet doors, and decorative panels for both safety and style.

- Sports and Recreation: Utilized in diving masks, safety goggles, and sports equipment for impact protection.

Where is Tempered Glass Required? – Building Codes and Safety Standards

Many local and international building codes mandate the use of tempered glass in locations where the risk of breakage is high and human contact is likely. These requirements typically apply to:

- Doors (including sliding and shower doors)

- Windows near the floor or within certain proximity to doors

- Staircase balustrades and railings

- Glass walls and partitions in public and commercial buildings

- Storefronts and entranceways

To ensure compliance and safety, always consult with experienced glass fabricators or a certified contractor when planning your project. Wondering if your project requires tempered glass? Contact us for expert guidance and a custom quote.

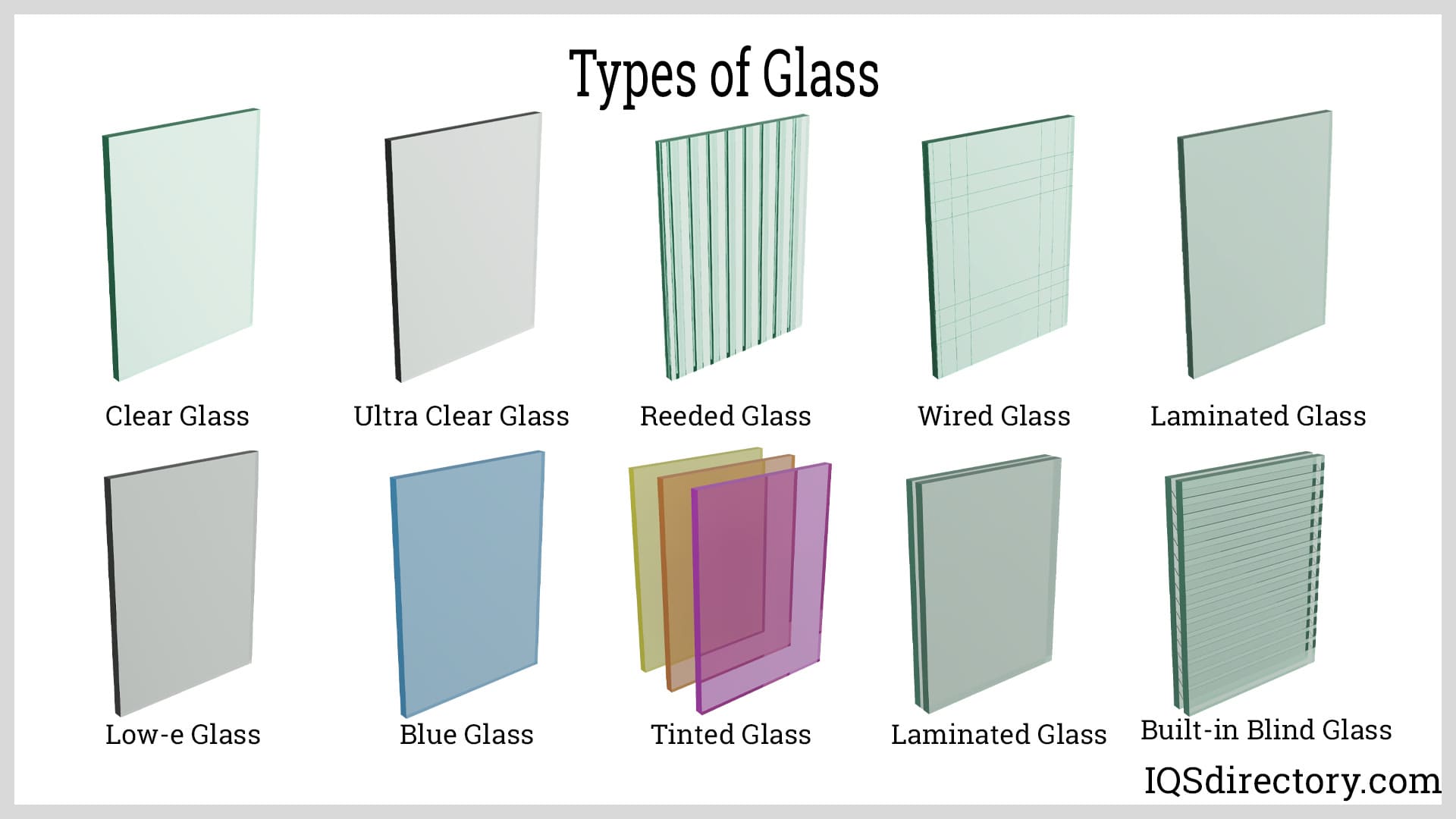

Tempered Glass vs. Laminated Glass – What's the Difference?

When selecting safety glass for a specific application, it is essential to understand the differences between tempered glass and laminated glass:

- Tempered Glass: Shatters into small, blunt pieces upon impact. Best for applications where breakage should not result in dangerous shards, such as side and rear automobile windows, shower enclosures, and glass doors.

- Laminated Glass: Composed of two or more glass layers bonded with an interlayer (often polyvinyl butyral, or PVB). If broken, the shards adhere to the interlayer, maintaining the glass's integrity. Commonly used for automotive windshields and skylights, where preventing ejection and maintaining visibility is crucial.

Which type of safety glass is best for your needs? Ask a glass expert for personalized recommendations based on your unique project requirements.

Potential Drawbacks and Considerations When Using Tempered Glass

While tempered glass offers exceptional durability and safety, it does have some limitations that buyers should consider before making a decision:

- Spontaneous Breakage: Tempered glass can occasionally shatter without warning, often due to undetected edge damage or inclusions (such as nickel sulfide particles) introduced during manufacturing.

- Irreversible Processing: Once tempered, the glass cannot be cut, drilled, or modified in any way—doing so will cause it to break instantly.

- Edge Vulnerability: Chips, nicks, or cracks at the glass edge can compromise its structural integrity and trigger shattering.

- Cost: While more expensive than standard annealed glass, tempered glass provides superior performance and safety, justifying the investment for many applications.

Understanding these factors can help you make an informed choice. Still unsure if tempered glass is right for your project? Contact our team for advice and a free estimate.

What to Consider When Buying Tempered Glass

If you are evaluating tempered glass panels or products for your next project, consider the following decision factors to ensure the best results:

- Glass Thickness and Size: Choose the correct thickness (usually between 3mm and 19mm) and dimensions based on structural requirements and intended use.

- Edge Finishes: Options like beveled, polished, or seamed edges can enhance both safety and aesthetics.

- Glass Tint and Coatings: Specialized tints and coatings can improve UV protection, glare reduction, and privacy.

- Certifications and Compliance: Verify that the glass meets relevant ANSI, ASTM, or EN safety standards for your market and application.

- Supplier Reputation: Work with reputable glass fabricators who can provide quality assurance, product traceability, and after-sales support.

- Customization: Many projects require custom shapes, sizes, holes, or notches—ensure these modifications are completed before the tempering process.

Are you searching for custom tempered glass solutions for commercial or residential projects? Request a quote from our expert team for fast, reliable service and competitive pricing.

Frequently Asked Questions About Tempered Glass

Is Tempered Glass the Same as Safety Glass?

Tempered glass is a type of safety glass, but not all safety glass is tempered. Laminated glass and wired glass are other forms of safety glass, each with unique properties and use cases.

How Can I Tell if Glass is Tempered?

Tempered glass typically has a small etched label or stamp in one corner indicating its safety rating and manufacturer. You can also identify tempered glass by its break pattern (granular pieces rather than sharp shards) or by contacting your supplier for verification.

Can Tempered Glass Be Cut or Drilled?

No, once glass is tempered, any attempt to cut, drill, or alter it will cause it to shatter. All modifications must be completed before the tempering process.

What Industries Use Tempered Glass?

Tempered glass is essential in a wide range of industries, including construction, automotive, electronics, home appliances, interior design, and hospitality. Its safety, strength, and versatility make it a superior choice for many demanding applications.

Is Tempered Glass More Expensive Than Regular Glass?

Yes, tempered glass generally costs more due to the specialized heat treatment and quality assurance processes involved. However, the investment is justified by its enhanced performance, safety, and longevity, especially in critical applications.

What Causes Spontaneous Breakage in Tempered Glass?

Spontaneous breakage is typically caused by internal imperfections or inclusions from the manufacturing process, such as nickel sulfide. Edge damage or severe impact can also trigger sudden shattering. High-quality manufacturing and careful installation can minimize these risks.

Why Choose Tempered Glass for Your Next Project?

Tempered glass stands out as a leading material for modern construction, design, and technology. Its combination of strength, safety, clarity, and versatility makes it an ideal solution for:

- Innovative architectural designs and facades

- Safe and stylish home interiors

- Impact-resistant commercial storefronts

- Durable automotive and transportation glass

- Protective panels and screens for electronics

- Custom furniture and décor applications

With so many potential uses and benefits, tempered glass empowers designers, builders, and homeowners to create safe, beautiful, and long-lasting environments.

Ready to Buy Tempered Glass? Get Started Today!

If you need custom tempered glass panels, doors, windows, or specialty products for your project, work with a trusted supplier who can meet your quality, compliance, and timeline requirements. Request a free quote or find a glass fabricator near you to discuss your specific needs. Our team is ready to help you select the right type of safety glass, answer your technical questions, and ensure seamless delivery to your job site.

Still Have Questions About Tempered Glass?

Whether you’re an architect, contractor, designer, or homeowner, choosing the right tempered glass solution is critical for safety, performance, and aesthetics. Let our team guide you every step of the way—from material selection and custom fabrication to delivery and installation. Discover the difference that expert glass fabrication can make for your next build or renovation.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services